Extreme high-strength fasteners crafted from advanced alloys have revolutionized industries like aerospace, mining, and oil & gas by enabling them to achieve unprecedented levels of performance. These components are designed to withstand ultimate tensile strengths surpassing 200 ksi, pushing the boundaries of engineering possibilities. This newsletter explores some of the most remarkable materials, highlighting their unique characteristics and specific applications.

**17-4 PH**

This age-hardened alloy can achieve tensile strengths ranging from 125 to 200 ksi, particularly excelling in the H900 condition where its yield strength outperforms standard 316 stainless steel by more than four times.

**NICHE:** Customizable strength through various age-hardened conditions.

**WASPALOY**

This age-hardened alloy can achieve tensile strengths ranging from 125 to 200 ksi, particularly excelling in the H900 condition where its yield strength outperforms standard 316 stainless steel by more than four times.

**NICHE:** Customizable strength through various age-hardened conditions.

**WASPALOY**

With an ultimate tensile strength just under 200 ksi, Waspaloy fasteners maintain exceptional strength even at elevated temperatures. They remain stable up to 1300°F, surpassing the performance of Inconel 718 in certain scenarios.

**NICHE:** Exceptional strength retention at extremely high temperatures.

**INCONEL 718**

With an ultimate tensile strength just under 200 ksi, Waspaloy fasteners maintain exceptional strength even at elevated temperatures. They remain stable up to 1300°F, surpassing the performance of Inconel 718 in certain scenarios.

**NICHE:** Exceptional strength retention at extremely high temperatures.

**INCONEL 718**

Known for its impressive strength at high temperatures, Inconel 718 also boasts outstanding corrosion resistance across a wide spectrum of media. Whether it's resisting oxidation or withstanding aggressive chemicals, this alloy stands out.

**NICHE:** A perfect blend of strength, temperature endurance, and corrosion resistance.

**MP159**

Known for its impressive strength at high temperatures, Inconel 718 also boasts outstanding corrosion resistance across a wide spectrum of media. Whether it's resisting oxidation or withstanding aggressive chemicals, this alloy stands out.

**NICHE:** A perfect blend of strength, temperature endurance, and corrosion resistance.

**MP159**

As one of the strongest alloys available, MP159 offers slightly lower tensile strength compared to its counterpart MP35N but compensates with superior heat tolerance, functioning effectively up to 1100°F.

**NICHE:** High strength combined with reliable performance at elevated temperatures.

**MP35N**

As one of the strongest alloys available, MP159 offers slightly lower tensile strength compared to its counterpart MP35N but compensates with superior heat tolerance, functioning effectively up to 1100°F.

**NICHE:** High strength combined with reliable performance at elevated temperatures.

**MP35N**

Boasting an ultimate tensile strength of up to 294 ksi, MP35N is among the strongest commercially available fastener materials. It remains functional up to 800°F and exhibits excellent corrosion resistance against mineral acids, hydrogen sulfide, and seawater.

**NICHE:** The ultimate choice for maximum strength and durability.

**When Strength Meets High Temperatures**

Boasting an ultimate tensile strength of up to 294 ksi, MP35N is among the strongest commercially available fastener materials. It remains functional up to 800°F and exhibits excellent corrosion resistance against mineral acids, hydrogen sulfide, and seawater.

**NICHE:** The ultimate choice for maximum strength and durability.

**When Strength Meets High Temperatures**

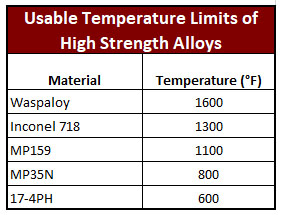

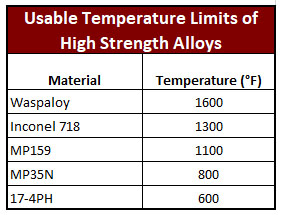

In environments demanding both high strength and extreme temperatures, selecting the right material becomes critical. The following chart compares the high-temperature capabilities of these alloys, helping engineers make informed decisions based on their specific needs.

While each alloy has its distinct advantages, understanding the nuances between them ensures optimal performance in challenging industrial settings. Whether you're working in aerospace, deep-sea drilling, or power generation, choosing the correct fastener material can significantly enhance operational efficiency and safety.

By leveraging these advanced materials, industries continue to innovate, achieving feats previously thought impossible. As technology evolves, so too will the demands placed on these fasteners—pushing manufacturers to develop ever-stronger solutions tailored to tomorrow’s challenges.

In environments demanding both high strength and extreme temperatures, selecting the right material becomes critical. The following chart compares the high-temperature capabilities of these alloys, helping engineers make informed decisions based on their specific needs.

While each alloy has its distinct advantages, understanding the nuances between them ensures optimal performance in challenging industrial settings. Whether you're working in aerospace, deep-sea drilling, or power generation, choosing the correct fastener material can significantly enhance operational efficiency and safety.

By leveraging these advanced materials, industries continue to innovate, achieving feats previously thought impossible. As technology evolves, so too will the demands placed on these fasteners—pushing manufacturers to develop ever-stronger solutions tailored to tomorrow’s challenges.

This age-hardened alloy can achieve tensile strengths ranging from 125 to 200 ksi, particularly excelling in the H900 condition where its yield strength outperforms standard 316 stainless steel by more than four times.

**NICHE:** Customizable strength through various age-hardened conditions.

**WASPALOY**

This age-hardened alloy can achieve tensile strengths ranging from 125 to 200 ksi, particularly excelling in the H900 condition where its yield strength outperforms standard 316 stainless steel by more than four times.

**NICHE:** Customizable strength through various age-hardened conditions.

**WASPALOY**

With an ultimate tensile strength just under 200 ksi, Waspaloy fasteners maintain exceptional strength even at elevated temperatures. They remain stable up to 1300°F, surpassing the performance of Inconel 718 in certain scenarios.

**NICHE:** Exceptional strength retention at extremely high temperatures.

**INCONEL 718**

With an ultimate tensile strength just under 200 ksi, Waspaloy fasteners maintain exceptional strength even at elevated temperatures. They remain stable up to 1300°F, surpassing the performance of Inconel 718 in certain scenarios.

**NICHE:** Exceptional strength retention at extremely high temperatures.

**INCONEL 718**

Known for its impressive strength at high temperatures, Inconel 718 also boasts outstanding corrosion resistance across a wide spectrum of media. Whether it's resisting oxidation or withstanding aggressive chemicals, this alloy stands out.

**NICHE:** A perfect blend of strength, temperature endurance, and corrosion resistance.

**MP159**

Known for its impressive strength at high temperatures, Inconel 718 also boasts outstanding corrosion resistance across a wide spectrum of media. Whether it's resisting oxidation or withstanding aggressive chemicals, this alloy stands out.

**NICHE:** A perfect blend of strength, temperature endurance, and corrosion resistance.

**MP159**

As one of the strongest alloys available, MP159 offers slightly lower tensile strength compared to its counterpart MP35N but compensates with superior heat tolerance, functioning effectively up to 1100°F.

**NICHE:** High strength combined with reliable performance at elevated temperatures.

**MP35N**

As one of the strongest alloys available, MP159 offers slightly lower tensile strength compared to its counterpart MP35N but compensates with superior heat tolerance, functioning effectively up to 1100°F.

**NICHE:** High strength combined with reliable performance at elevated temperatures.

**MP35N**

Boasting an ultimate tensile strength of up to 294 ksi, MP35N is among the strongest commercially available fastener materials. It remains functional up to 800°F and exhibits excellent corrosion resistance against mineral acids, hydrogen sulfide, and seawater.

**NICHE:** The ultimate choice for maximum strength and durability.

**When Strength Meets High Temperatures**

Boasting an ultimate tensile strength of up to 294 ksi, MP35N is among the strongest commercially available fastener materials. It remains functional up to 800°F and exhibits excellent corrosion resistance against mineral acids, hydrogen sulfide, and seawater.

**NICHE:** The ultimate choice for maximum strength and durability.

**When Strength Meets High Temperatures**

In environments demanding both high strength and extreme temperatures, selecting the right material becomes critical. The following chart compares the high-temperature capabilities of these alloys, helping engineers make informed decisions based on their specific needs.

While each alloy has its distinct advantages, understanding the nuances between them ensures optimal performance in challenging industrial settings. Whether you're working in aerospace, deep-sea drilling, or power generation, choosing the correct fastener material can significantly enhance operational efficiency and safety.

By leveraging these advanced materials, industries continue to innovate, achieving feats previously thought impossible. As technology evolves, so too will the demands placed on these fasteners—pushing manufacturers to develop ever-stronger solutions tailored to tomorrow’s challenges.

In environments demanding both high strength and extreme temperatures, selecting the right material becomes critical. The following chart compares the high-temperature capabilities of these alloys, helping engineers make informed decisions based on their specific needs.

While each alloy has its distinct advantages, understanding the nuances between them ensures optimal performance in challenging industrial settings. Whether you're working in aerospace, deep-sea drilling, or power generation, choosing the correct fastener material can significantly enhance operational efficiency and safety.

By leveraging these advanced materials, industries continue to innovate, achieving feats previously thought impossible. As technology evolves, so too will the demands placed on these fasteners—pushing manufacturers to develop ever-stronger solutions tailored to tomorrow’s challenges.Toilet Seat bolts are key parts that connect the toilet seat to the ceramic base. Their quality directly affects the stability and service life of the seat. Our products cover a variety of materials, functions, and scene requirements to cater to bulk buyers, wholesalers, and OEM partners.

Toilet seat bolts,Toilet seat screws,Toilet lid screws,Toilet lid bolts,Toilet bowl seat screws

Yangzhou Mifen Import and Export Co., Ltd , https://www.fanmitrkwc.com